-

Recent Posts

Recent Comments

Category Archives: Uncategorized

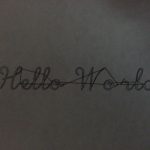

CNC Machine: Plotting Images

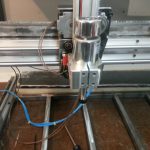

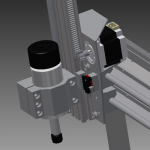

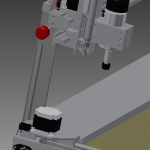

It’s been a while since I’ve updated, and I’ve gotten a lot done during this time. I modified the gantry motor plate (one of them at least) to include a spring tensioner and also added some diagonal braces to the gantry columns; the gantry now runs even smoother and with little or no backlash. I then added the Y axis guides, fabricated the Y axis motor carrier and Y rack support. Once I got all the Y parts together I was able, for the first time, to test coordinated motion between axes by clamping a pen to the Y axis. The results of this testing were great. It drew very accurately with the pen, the drawing path even occasionally required overlapping the same pen line later in the program; it was able to follow the existing lines exactly. The only thing it couldn’t do was lift the pen, since the Z axis wasn’t installed…

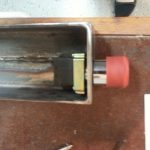

…So after I eventually finished playing with plotting images I began work on the Z axis. The biggest challenge with this was attachment of the spindle mount; the spindle mount is one of the few metal things (other than the motors/guides/racks) that I didn’t fabricate from scratch; despite this I still needed to do some fairly extensive machining/modification to get it attached to the Z extrusion in a very secure but still adjustable way. With the spindle mounted to the Z extrusion the remainder of the work was just some minor drilling, tapping, and cutting. The Z rack is a lot longer than it needs to be for the amount of travel Z has; it was the last rack section to get cut so the extra length is just the leftover/spare, it fits on the extrusion so no sense cutting it off.

Sometime during initial gantry testing I fried the Z axis motor driver on the smoothieboard when moving the gantry by hand with the drivers off. Z wasn’t even connected during this but my guess is the spinning gantry motors fed back through their drivers onto the supply bus; Z happened to be the weakest and it fried with a snap & flash. Because of this I was actually testing the Z axis with the Y driver. I have an external stepper driver on the way and once it arrives I should be able to move all axes at once and really see what it’s capable of. Next Steps:

#1 – Finish electrical enclosure fabrication

#2 – Modify other gantry motor plate to include spring tensioner

#3 – Final fabrication of cable management, cosmetic covers, etc.

#4 – Disassemble, body work, prime, paint

#5 – Final reassembly & wiring

CNC Machine: Gantry Moving

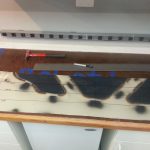

Lots of fabrication work over the past week including the motor brackets, columns, and home switch trigger. The gantry axis (still debating whether to call this X or Y) guide rails as well as many other parts arrived Friday and were mounted to the machine base. The machine base also got a coat of body filler (the pink spots in the photos) and sanding in anticipation of paint.

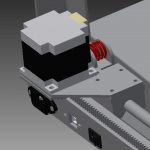

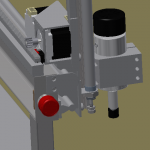

With everything fabricated and assembled, I was able to temporarily wire the system and run the first motion tests of the gantry. Overall I was extremely impressed, the homing switch worked and both sides stayed perfectly in-sync. The gantry achieved the same 1200IPM I had seen in the rack testing. I somehow managed to build it with tight enough tolerances that the rack doesn’t bind and isn’t overly loose over the full travel range, but there are still some noticeable differences in some spots. Right now the mesh is only adjustable with the play in the motor mount screws. One improvement I’ve already got on the drawing board (screenshot below) is to add a spring tensioner system to keep the rack mesh constant across the entire travel. There was enough room where I won’t have to re-build anything to do this, it almost looks like I planned to have it from the start.

Also, in aviation news, this weekend I passed the phase check to be able to fly solo cross-country. I’ve been able to fly solo for a while but only within the local airport area; this now means I can fly solo between airports and continue practicing cross-country flying.

CNC Machine: Frame Progress

This weekend I did more work on the CNC machine base:

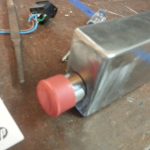

– Power inlet, power switch, USB port, and E-Stop holes were all drilled & filed to the correct shapes.

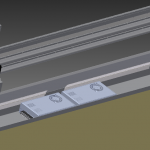

– Rack support rails were added to the frame edges and end-caps added to the frame front and gantry ends.

– Flame straightened the frame to relieve welding stress/distortion. It was my first time trying this so I wasn’t sure about it at first, but it worked great. I put a straightedge on the frame and found which side was convex; then heated that side in several places until it was just red hot. After it cooled the straight edge showed a much smaller gap in the middle on the concave side; I repeated this until the frame was flat in all directions.

– Flame straightening got the frame flat overall, but there were still a few high-spots. These were ground down with a flap wheel until no gaps existed with the straight-edge and the entire frame was perfectly flat.

– Machined holes into the gantry drive racks. The clearance between rack edge and the inside edge of the rack teeth was extremely close. I bought some extra room by grinding down the outside diameter of the bolts some, but it was still very close. For the most part I was able to get the holes centered exactly in in this small space, but there were a few holes that created a notch in the outside edge of the rack; luckily none of the holes interfered with the rack teeth. The other racks will be easier since they’ll be mounted from the back side with partial depth holes drilled/tapped into the back.

There’s still some fabrication work left to do, but several critical parts (Guides, spindle, etc.) are all on a slow boat from various far east locales. They’ll become the limiting factor, so I’m taking it slow and making sure everything is done as well as it can be.

CNC Machine Fabrication Begins

The metal has arrived and over the last few nights I’ve begun fabrication of the machine. For the electronics enclosure I’m re-purposing the original crumpled hood that came with the golf restoration project. After removing the inner support, the outer hood skin was a reasonably flat piece of sheet metal. (That does also make this machine part VW, but it wasn’t intentional) I don’t have a big press brake for accurate bends, so the box that resulted is a little wonky, but its nothing that can’t be salvaged with some body filler and sanding.

I’m moving fairly slowly with the machine base, making sure everything is as square, flat, and true to the design as my ability to measure, and so far it’s looking really good. I also have the gantry mostly fabricated, which consists of two pieces of angle iron welded edge-to-edge, forming a channel.

Remaining:

– Fabricate gantry columns

– Fabricate motor plates

– Fabricate Z axis mounting plate

– Fabricate electrical enclosure lid & connect to base w/ piano hinge

– Machine base flatness check and hand scraping of guide mounting ways

– Drill & tap holes (dozens of them) in the machine base and racks for mounting the racks and guides

– Assemble/Wire/Test

– Disassemble, Paint, & Reassemble

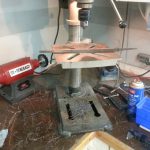

Stepper Motor Testing

The racks, pinions, and power supply arrived yesterday and I setup a trial run to verify the motors would have enough speed/torque with the selected gear ratio. First, I bored a few thousands out of the pinions to allow a press-fit onto the stepper shafts. Next I pressed the pinions onto the stepper shafts; luckily the steppers have a hole in the back of the case that allowed me to support the other end of the motor shaft so that no force went through the motor bearings. I then verified the pinion/shaft run-out with a dial indicator; all except one were well under a thousandth. I was able to bend the one with a few thousandths run-out to match the rest; there was no way to protect the motor bearings during this process though so hopefully I didn’t cause any longevity problems.

Once all the pinions were in place I cut the racks to final length and modified the Smoothieboard electronics and configuration files to accommodate a 2nd (and inverse rotation) motor on the X axis. I then wired it all up and began testing. It all seems to work great and I was getting what seems to be plenty to torque all the way up to 1200in/min. The rack also seemed to have very little backlash, even over a range of different engagement depths. I don’t have any good way to measure the torque, so I just pushed against the rack by hand with a force that I assume is far greater than the moving/cutting resistance. So it remains to be seen if 1200in/min will be the actual speed; I also verified there is even more torque at lower speed, so I can always slow it down if need-be. Speed will probably be limited more by the spindle/tooling/material anyways.

CNC Machine Planning Pt2

Since the last update I’ve completed the machine design and ordered a majority of the metal and mechanical parts. Some of the components’ 3D models (smoothieboard, power supply) were available online, which saved some time, but I had to model the majority from scratch. The design uses all the actual part dimensions to ensure there won’t be any part interference and that the range-of-motion will be OK. Getting the dimensions right so that there is no interference while also not having any wasted travel is actually much harder than it looks and a lot of time was spent perfecting this. As a result, the clearances are fairly tight, but this machine is meant to be as compact as possible so this is intentional. The overall usable table size worked out to be 48″x18″, with a machine footprint of 52″x24″. Some design highlights:

- Strategically placed bolted connections to allow for adjustment of squareness and rack/pinion mesh.

- Minimize weldment complexity and dimension criticality. It will still require a lot of attention during fabrication, easily the most dimension-critical thing I’ve fabricated.

- X rails flush with the back of the table to allow for future expansion.

- Parts will be held to the table with temporary clips screwed into a sacrificial fiberboard table;when the fiberboard becomes too full of screw holes it will be replaceable. The spindle centerline will be able to reach every part of the table to allow it to be surfaced flat.

- The electrical enclosure occupies the rear area that is unreachable by the spindle. Unfortunately the height of the power supplies makes the enclosure higher than the table surface, so if the machine needs to be temporarily expanded I’ll have to build up the table surface over the enclosure and sacrifice some Z travel. This won’t be a big problem though since the type of things I’d do in ‘expanded table mode’ wouldn’t require much Z anyways. (Making the base taller would have fixed this, but since it’s going to live on the workbench all the time I’d rather keep the base as flat as possible)

- Z axis uses a standard extrusion; this will give the most flexibility with mounting different tools

- I included a provision for a pneumatic cylinder in the design to counter-balance the Z axis. This will allow the Z axis weight to be precisely offset by adjusting air pressure. I’ll wait and see how it works though before deciding to either add this, a gas strut of the same size, or nothing.

CNC Machine Planning

I’ve had on my list for a long while now that when the bus was ‘done’ I’d get back into hobby electronics/robotics. I can’t think of a better way to kick this off than by creating a CNC machine; it’s a fun project on it’s own but will also make many of the miscellaneous fabrication tasks for projects of all categories (hobby/bus/home) easier, faster, and of much higher quality.

Design Requirements:

#1 – More or less fit within a 4ft wide by 2ft deep x 20in tall area; allowing it to live full-time on the garage workbench without being in the way. Also attempt to minimize deck height and park moving axes flat against the back wall for the same reason.

#2 – Be able to cut 4×8 material if needed. (Does not conflict with #1, design just needs to allow for future temporary extension & relocation)

#3 – Initial build will be a router, but the design needs to be flexible enough to support future tool types (3D printer extruder, drag knife, low power laser, etc)

#4 – Accurate enough for #3; maybe +/- 10 thou?

#5 – Rigid enough for #’s 3 & 4, but not to the extent that it becomes an immovable object like a Bridgeport.

#6 – Faster than a snails pace but speed isn’t all that important, not a production line machine.

#7 – Reduce cost to the lowest possible while maintaining good quality. Utilize all welding/machining/painting skills learned in other projects to build mostly from raw materials to save cost. Utilize “off-the-shelf” components in creative ways.

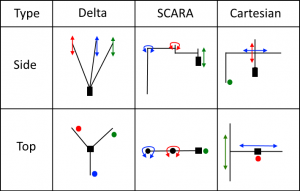

As far as machine configuration goes, the choices are: Delta, Cartesian, or SCARA. I made a quick sketch of the simplest forms of each below. Although the delta configuration is currently very popular in the 3D printing world, I immediately ruled it out as being incompatible with my size and tooling requirements. A SCARA configuration was very tempting as it could fold itself up into one corner when not in use. I had to rule it out though because the geometry is just too weird for my liking, all limits and resolution are polar; in other words the resolution changes with distance away from the base and the machine limits are circular instead of rectangular. This left me with the tried-and-true Cartesian configuration.

I’ll base the controls on the open source SmoothieBoard project, which itself is based on the open source GRBL (pronounced ‘Gerbil’) project. I’m confident I could have designed/built/programmed this all myself from scratch and it would have worked, but wouldn’t be quite as good as a well developed community-based project and I’d rather just focus on getting the overall project up and running. The SmoothieBoard will directly drive at least three 2A stepper motors (X/Y/Z), and perhaps also a 4th motor working in parallel with one of the others depending on the mechanical design.

I’m dusting off my old student copy of Autodesk Inventor and beginning on the mechanical design now. It’s still very much in the initial stages and I’d rather build it digitally 20x and physically once, so it may take a while to perfect to the point of beginning construction. Currently some of the brainstorming questions are:

Machine frame?

Black Pipe: +Cheapest Option, +Cast Iron good at damping, -Bad Tolerances, -Weldability Questionable

Mild Steel Tubing: -/+ Good middle ground between other two options?

Aluminum Extrusion: +Quick assembly, +Good Tolerances, -Expensive, -“too easy”/looks-like-an-erector-set

Drivetrain?

Rack & Pinion: +McMaster has decent looking sets for reasonable cost, +Easy to extend, -Backlash

Ballscrew: +Low Backlash, -Even the ‘cheap’ ones are expensive, -Impossible to extend temporarily

Belt or Chain: +Simple to experiment with ratios, -Difficult to extend temporarily, -Stretch/Backlash

Linear Guides?

Homemade: +Design Flexibility, -Requires complex fabrication of slides w/ small bearings

Bought: +Known-good performance, -Expensive, -Limited length/size options

Is there a 3rd option? Possible to buy slides to use with some nominal tubing size?

Adding Auto-Refill to Keurig

It’s not that manually refilling a Keurig tank is hard, it’s just unnecessary. Commercial Keurigs (and some of the high-end home versions) are built with this in mind and can be directly plumbed for water. Our Keurig, however, is a ‘normal’ home machine without provisions for direct plumbing; so some creativity was involved in adapting it for this feature. Altogether this was a fairly simple 3-step process:

#1 – Make bracket from scrap piece of PVC pipe.

#2 – Install miniature float valve ($3 w/ free shipping) and bracket into tank.

#3 – Plumb float valve to existing water filter under sink.

All plumbing is nicely concealed behind the microwave/cabinets, so the only evidence of anything different is the float visible in the tank. Before anyone freaks out about the evil toxic plastic floating in the water, I should point out that the tank itself is plastic anyways, as is much of the tubing that supplies water to the faucet when filling the old-fashioned way. Total project cost was well under $10.

Winter Update

Aviation: Winter is here and with it has come lots of overcast weather that’s no good for flight training, slowing progress quite a bit. In total I’ve now soloed 6-8 times and have started working on cross-country training. Cross-country flying adds many new elements: flight planning, talking to Air Traffic Control, radio navigation, visual navigation by waypoints, etc. All this has to be done while still flying the plane, so it’s definitely a challenge. Currently targeting to have my FAA checkride sometime before April.

Bus: Winter also puts a damper on bus driving since I don’t have the heat connected yet. On the last drive before the temperature dropped I had a big loss in power every few minutes and had to pull over and idle before power came back. I haven’t looked into it yet but this seems consistent with a clogged fuel filter; I was expecting the first filter to go quickly since it’s filtering out all the rust/varnish/trash from the fuel tank that sat for 30 years. I probably could swap the filter and have it going again but I think this is a good opportunity to now pull the engine/trans again and go through it with a fine-tooth comb with the goal of getting it smoother/quieter/stronger to enable longer trips. No immediate plans to do this, probably when the weather warms up.

Tech Projects: I just ordered a float valve to automate refilling the Keurig, I’ll post pictures of how that goes. Also I’m getting interested in making a small CNC machine; I’ve had this on my long-term to do list for a while but recently component prices have dropped substantially so I’ve started the planning process.

First Solo Flight!

Originally this weekend was to be my first solo flight. Sunday I showed the instructor 3 takeoffs, 3 landings, and got signed off to fly solo. Just as we taxied back to the ramp to let the instructor out though, the weather report changed and exceeded the limits that I’m signed off for (12knots total wind, up to 5knots crosswind component). Because of this, we delayed the actual solo until this evening after work.

So today I was back at the field and everything went well. There’s a tradition in aviation that when a student first solos the instructor cuts off the student’s shirt tail; supposedly this dates back to the early days of biplane aviation when the instructor sat behind the student and pulled on the student’s shirt tail to get attention. When I taxied back to the ramp my instructor was ready with scissors…

I’m told it goes relatively quickly from here but I know there’s a lot left to learn; I’ll now do some practicing on my own and then we’ll get into cross-country flying and procedures for ATC communication.