-

Recent Posts

Recent Comments

Category Archives: Uncategorized

Using a Real Aviation Headset with a PC Simulator

In parallel with real-world flight training I’ve begun to use a PC flight simulator more seriously. This reinforces what’s learned in the real plane and also allows me to practice flights ahead of time. The simulator is only vaguely analogous to real flying though, so the more I can do to make it realistic the better. One realism point would be to use the real aviation headset, but the headset does not directly plug into the PC. After a good bit of research cross-referencing part numbers and checking schematics, I came to two critical conclusions:

#1 – Standard 1/4″ mono audio dimensions are the same as general aviation headset plug dimensions. (The speaker plug, not the microphone plug)

#2 – The sound card output levels are compatible with the headset’s required input level. (not so low that they’d be inaudible, and not so high that they’d blow out the speakers on even the lowest setting)

Once those realizations were made it was easy enough to make an adapter cable from a scrap audio cord and a $2 1/4″ mono jack. There are ready-made adapters online, but these go for far more then even the standard 5X markup for anything with ‘aviation’ in the description; so it was worth the effort to spend a few minutes and build myself. The microphone connector is more special-purpose and would require finding the special jack and likely some circuitry to make the levels work for the PC mic input, I don’t do anything in the simulator that requires the microphone though, so that connection just stays unplugged.

Golf Coolant Leak Repair

A few weeks ago the Golf gave a low coolant warning and, not seeing any immediate signs of a leak, I topped if off. This week, I noticed a few pink drips in the garage. This is actually fortunate because it meant there was an external leak of some kind rather than something more serious like an EGR cooler or head gasket leak. Since the puddles were rapidly increasing in size I investigated the source of the leak tonight. Unfortunately it wasn’t anything as easy as a bad hose, clamp, or o-ring; I could see coolant dripping from the radiator. The next step, as it is with most modern VW repairs, was to disassemble the entire car. Although it looks intense, cleaning up the garage prior to starting this project took about as long as actually accessing the radiator.

From searches online it appears this is a somewhat common problem; the fan support vibrates against the thin aluminum radiator tubes until a hole is worn through. During reassembly I’ll add some rubber cushioning in this area to prevent recurrence. A replacement is available locally and I’ll pick it up after work tomorrow; I should be able to have everything back together tomorrow night, though I may let the project stretch into the weekend to thoroughly clean/detail the front bumper while I have everything apart.

Update: Finished this Friday night, relatively easy, no more leak.

Carpentry & Aviation

Today (I have a few days off of work), after a few months of studying in my spare time, I finally took the controls of a Cessna 172 for about an hour. With direction from the instructor I taxied, took-off, climbed to 2000ft, and then maneuvered around and even did part of the landing approach; though the instructor did the landing itself. I’ve got a long way to go but over then next year or so I’ll be flying somewhat frequently to make progress towards a private pilot certificate. Anytime a new skill can be learned (i.e. welding/painting/etc from the bus project) I find that it can be beneficial in unexpected ways, even for seemingly unrelated tasks/problems. So this is about having another tool in the mental toolbox, and I’ve always been interested in aviation anyways…

After arriving back from the flight I starting working on installing crown molding in the downstairs bathroom. For some reason this was the only room in the house that didn’t have it and I always thought it looked odd. In the past, I’ve just propped the molding up at the correct angle and hand sawed at 45degrees in a miter box. Due to the number of joints though I decided to get fancy and make the cuts on the tablesaw. This presents a problem since, when the molding is flat on the table, the angles are in two different directions: a compound angle in which the blade must be tilted and the material angled against the push fence. Luckily I’m not the first person to ever do this so I found tables online of compound angles for a given wall angle (90deg nearly always) and a given trim angle (the angle the trim sits against the wall). There was some scrap made while learning what orientation to use for a given angle; 4 of the 8 combinations don’t make anything useful (i.e. inside right/outside left/etc.) More than a few times during this process I thought back to how much easier flying the plane was (or at least seemed) earlier in the day.

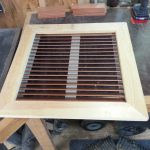

Building a better air return

Today, as part of a repainting project, I constructed a new air return out extra slats from wooden blinds and some scrap wood. Nothing was wrong with the existing metal return other than being ugly, so it will get added to the scrap metal pile and possible used on some metalwork project. All the materials were scraps from other projects, so total cost was just some paint/glue/staples and a few cents of electricity. As a bonus, the new return seems to be quieter and less restrictive than the metal version.

Successful Return & Next Steps

The bus made the trip back from Charleston uneventfully. It was loaded at least half full with various wedding stuff, luggage, tools, etc. We had originally thought of having the bus ready for the wedding as a bonus, but in retrospect it was actually a large part of the wedding logistics and things wouldn’t have gone as smoothly without it.

Having performed admirably for the wedding trip, the bus will now get a bit of a vacation over the winter. During this time I’ll have the engine/trans out again for closer inspection; the trans will need to be either rebuilt or replaced in order to get more speed while also bringing the interior noise levels down. I’ll also work on the interior, paint touch-ups, and various other miscellaneous stuff during this time.

I’ll continue to post updates as these changes are made; but the format of the site may quickly change as I incorporate more ‘non-bus’ projects.

Wedding Errands

The bus has been very useful for all the miscellaneous errands required leading up to the wedding; it’s also been very popular (too popular!) with passers-by in downtown Charleston and on Kiawah island. We had to run an errand in Mt Pleasant today which necessitated the bus hauling itself over the 3rd longest cable-stayed bridge in the western hemisphere. It was windy up there but the bus did OK and even kept up with traffic.

Giant Spider

Yet another giant spider, this time in the garage. It stayed still long enough to get a ruler next to it.

2011 Golf Rebuild

I had been keeping an eye out online for a very specific car: 2010+ 4dr golf TDI w/ sunroof and 6spd, in any color other than the ubiquitous VW silver. Each of these criteria alone are the low-volume options in the US; in combination it means that there are only a few for sale anywhere along the east coast at a given time. So when I did occasionally see one it was either exorbitantly priced or wrecked beyond repair. When I came across this one with relatively superficial damage at a reasonable price I went for it and spent a few weeks of nights/weekends bringing it back to new. In this case I had a body shop do the paint since I’m not ready to venture into metallic painting yet; runs cannot be wet-sanded out of metallic paint like they can on the bus’s non-metallic paint.

The summer has also been busy with traveling and house/yard projects, hopefully I’ll get back to working on the bus soon.