Engine & Fuel Tank Installed

Today I installed the fuel tank and engine. The engine bay has not been repainted, but the goal at this point is to get it drivable; the engine is easy to remove, so the engine bay can be restored relatively easily at a later date. Also, I have a limited amount of blue paint, it should be enough for everything but just in case it isn’t I’d rather the second batch be used for the engine compartment than running out somewhere on the outside.

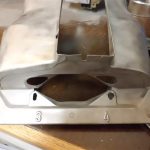

Engine Assembly Continued

Big Parts Blasted

Today the remaining unblasted parts that were too big for the blast cabinet were media blasted outside. The parts were then hung up and primed. Many of these parts will be black, I should have the black paint completed in the next few days.

Engine Parts Ready for Paint

Engine Cleaned

I cleaned the engine and checked everything out. I had noticed that it would lock up just short of completing a full rev so I pulled the cylinder heads and discovered a small piece of metal in cylinder #2. The origins of this piece of metal are unclear but there is no damage anywhere, so it does not appear that this happened while it was running. The intake manifold has been off for some time now so the metal piece probably just fell into the open intake port. Overall it’s in great shape with very little wear and good compression, I have a gasket kit on the way since some of the seals are questionable and they’re much easier to replace now then when everything is back together.

Best of all, the lightweight magnesium construction means I can, for now at least, move it around by hand.

Engine Tins Media Blasted

Work began on the various sheetmetal parts (known in VW vernacular as “tins”) that direct air to and through the cylinder cooling fins. Being aircooled instead of watercooled, this is one area where the bus has much more in common with a modern light aircraft than any modern road vehicle. These parts are all thin steel and have been exposed to years of extreme vibration and temperature fluctuations; because of this there were many stress cracked spots that required welding.