The forward cargo door was hung in the door opening and many tweaks were made to achieve a consistent panel gap around all three sides. Previously the rusty/warped bottom of the cargo doors caught against the floor, causing the bottom of the doors to bow outwards. Also, the quarter panel patch was fitted, welded, and ground. The quarter panel still needs to be plug welded to the flanges that intersect it from behind; once this is completed the repair will be 100% complete.

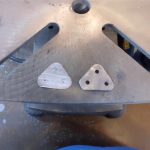

Front bumper disassembly

Bus Bubble v2.0

The bus was moved 90 degrees again to the other garage bay. The original bus bubble worked well but had the disadvantage of blocking both garage bays. The new-and-improved version only takes up one bay while staying roughly the same size inside. Structure was also added at key points to prevent the sides from sucking in too much when the exhaust fan is turned on.