Lower Passenger Side B Pillar Repair

The bottom of the passenger side B pillar had rusted through. The rusted section was cut out, a custom piece was cut, bent, and then welded in. Also, the passenger side cargo floor repair section that I installed years ago was a generic repair piece that fit buses from the late 1950’s through 1967. Somewhere in that date range the size of the seat mounting plate shrunk. The repair piece had included the larger size plate, so I trimmed it to match the three remaining original plates.

Front Bumper Overrider Repaired

The bottom of one of the front bumper overriders was rusted through. The overrider parts are what makes this the “US-only” version of the bus bumper; buses sold outside the US & Canada did not have the overriders. The overriders and bumper are in generally OK condition after the repair. Some dents will be smoothed later, but I do plan to leave some ‘character’ on the bumpers.

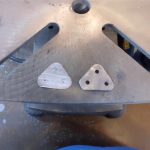

Pop-out Window Bracket Repair

Another part for the “why did they cut that off!?” category. For some reason the pop-out window bracket for the first window behind the driver’s side door had been chopped off. Luckily the same bracket is used on 3 other windows and I was able to create a paper template by rubbing over an existing bracket with pencil/paper. Once the new bracket was shaped, drilled, and tapped it was welded in place. The picture makes the grind marks look deeper & messier than they actually are; after the next primer coat the new bracket should look as good as the factory brackets.

Spare Tire Bracket Installed

At some point in the bus’s past most of the spare tire bracket was removed, leaving only about 1/4in of the original bracket. A donor bracket was located and after a bit of prep work it was welded onto the left rear cargo wall. The position of the remains of the original bracket were used as a guide.

Miscellaneous Metal Repair

Cargo door removal, Spare tire well patch, and window sandblasting

The 8 large Phillips head bolts holding on the cargo doors were removed after much heating, hammering, and some cutting. The cargo doors were removed and a patch was created/installed for the floor of the spare tire well. All window frames were then sandblasted and nearly all paint stripped from the inside/outside of everything above the trim line.

Patching begins on spare tire well wall

Mysterious Hole Patched

At some point in the bus’s history a previous owner cut a hole behind the back seat row. This was probably done to bring in warm air to make up for a poorly maintained heating system. The hole was cut on an un-ribbed section of floor, making for a fairly simple patch. Prior to this repair the gas tank was taken out to avoid any fiery surprises.