Lots of fabrication work over the past week including the motor brackets, columns, and home switch trigger. The gantry axis (still debating whether to call this X or Y) guide rails as well as many other parts arrived Friday and were mounted to the machine base. The machine base also got a coat of body filler (the pink spots in the photos) and sanding in anticipation of paint.

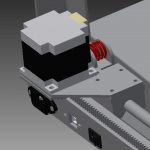

With everything fabricated and assembled, I was able to temporarily wire the system and run the first motion tests of the gantry. Overall I was extremely impressed, the homing switch worked and both sides stayed perfectly in-sync. The gantry achieved the same 1200IPM I had seen in the rack testing. I somehow managed to build it with tight enough tolerances that the rack doesn’t bind and isn’t overly loose over the full travel range, but there are still some noticeable differences in some spots. Right now the mesh is only adjustable with the play in the motor mount screws. One improvement I’ve already got on the drawing board (screenshot below) is to add a spring tensioner system to keep the rack mesh constant across the entire travel. There was enough room where I won’t have to re-build anything to do this, it almost looks like I planned to have it from the start.

Also, in aviation news, this weekend I passed the phase check to be able to fly solo cross-country. I’ve been able to fly solo for a while but only within the local airport area; this now means I can fly solo between airports and continue practicing cross-country flying.