S4 Coolant Leak Tool

I noticed a small coolant leak on my car recently. It wasn’t clear where it was coming from, only that it was somewhere in the front and only occurred after running for some time. To help troubleshoot this I created a 3d printed adapter that interfaced a tire schrader valve to the coolant tank, sealed with an O-ring. An F clamp held this adapter in place and I pressurized the coolant system to a few PSI. This lead to the discovery of a bad O-ring on one of the coolant crossover pipes at the supercharger, which was easily fixed.

Bus back together

This weekend the transmission arrived and I got everything back together. While waiting on the transmission I completed a few miscellaneous things:

- Replace bearings in the dynamo/generator (it’s not an alternator like in ‘modern’ cars)

- Fabricated replacement clutch cable, including making a new end link on the lathe. The end links were then crimped onto the cable with the 12 ton hydraulic press and soldered in place, so they shouldn’t be going anywhere.The clutch cable had partially broken and was stretching with each press, causing the clutch not to disengage all the way. This is what took the bus out of commission in December. Since it was still connected at both ends and not completely loose it seemed OK until I removed the pedal pan and saw many broken wires.

- Fabricated the special barrel nuts needed to connect the heater control cables to the exhaust heater boxes.

The test drive went very well, it’s noticeably smoother but noise levels are still quite high inside. Part of the noise level is a minor exhaust leak that I’m tracking down, but the new smoothness also allowed me to notice for the first time that a majority of the noise is from the axle reduction boxes. This was confirmed by carefully running in 2nd gear with the back wheels on jack stands – the bearing rumble then became even more noticeable. Replacement bearings are on the way and I should be able to swap them out with the engine/transmission still in place.

Bus Engine Rebuild – Part 2

This weekend I started putting the engine back together, and I’ve decided to replace a number of parts:

- Camshaft – A few of the lobes were worn down, limiting valve lift. Replaced with a very mildly modified cam that will provide more power to go along with the new higher transmission ratios.

- Lifters – Lifters had worn slightly concave rather than the correct slightly convex.

- Connecting Rods – All rods weighed the same but were not balanced end-to-end and there was not enough material left to grind off and correct the problem.

- Bearings – The bearings were OK but it’s easy enough to replace these while the case is open.

- Pushrod Tubes – These could have been reused but were a little beat up and now is an easy time to replace, ensuring no leaks.

- Oil Cooler – The old cooler was made in 1971, no telling how much build-up there was inside preventing heat transfer. Replaced with a larger cooler from a later engine style.

It’s mostly reassembled now, including shimming the crank/flywheel for proper end play and verifying with a dial indicator to 0.001″ (end play is critical on aircooled VW’s). I also modified the fan shroud to accept the bigger oil cooler and also re-built the thermostat. The thermostat is a sealed copper accordion that expands when heated. For some reason mine had expanded permanently; these are no longer made and becoming increasingly rare, so I had to fix it. Luckily I was able to find information about others who have had the same problem and I was able to fix it in the same way; the fix consisted of unsoldering the end plate, compressing the accordion, dropping in a bit of rubbing alcohol, and resoldering the plate before it had a chance to evaporate. The thermostat is now completely contracted at room temp and begins to expand around 80°C, allowing it to push on a linkage that opens cooling flaps in the fan shroud.

The new bearings are “structurally guaranted[sic]”, hopefully that’s just a typo and not a clever way to dodge claims – “they weren’t guaranteed, they were guaranted”

Bus Engine Rebuild

A slight change of direction with the transmission rebuild. I was looking forward to going through the transmission and readjusting everything to make it work again, but to get more speed I would have needed to swap out the ring/pinion gear as well as 4th gear. The cost for these gears separately was not too much different from the cost of a rebuilt transmission that included these gears. Because of this, there’s a rebuilt transmission on the way that already has the ‘correct’ gearing. Since this is a hobby I normally don’t think about time too much, but this also buys me a lot of time that gives me a chance to instead go through the engine while I’m waiting for the transmission to arrive.

I started going though the engine this weekend. There wasn’t anything necessarily ‘wrong’ with it, but it was put together somewhat hurriedly prior to having the bus at the wedding; I’ve since had a chance to second-guess a few things I did, especially with balance. I stripped it down to the case and this time gave it thin coat of black paint; heat has been an ongoing issue and changing the color to flat black will actually improve heat dissipation slightly. Overall everything looked good, bearing wear looked normal.

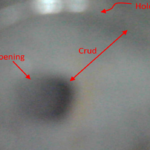

Golf Coolant Leak Repair

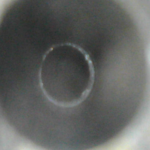

A few weeks ago the Golf gave a low coolant warning and, not seeing any immediate signs of a leak, I topped if off. This week, I noticed a few pink drips in the garage. This is actually fortunate because it meant there was an external leak of some kind rather than something more serious like an EGR cooler or head gasket leak. Since the puddles were rapidly increasing in size I investigated the source of the leak tonight. Unfortunately it wasn’t anything as easy as a bad hose, clamp, or o-ring; I could see coolant dripping from the radiator. The next step, as it is with most modern VW repairs, was to disassemble the entire car. Although it looks intense, cleaning up the garage prior to starting this project took about as long as actually accessing the radiator.

From searches online it appears this is a somewhat common problem; the fan support vibrates against the thin aluminum radiator tubes until a hole is worn through. During reassembly I’ll add some rubber cushioning in this area to prevent recurrence. A replacement is available locally and I’ll pick it up after work tomorrow; I should be able to have everything back together tomorrow night, though I may let the project stretch into the weekend to thoroughly clean/detail the front bumper while I have everything apart.

Update: Finished this Friday night, relatively easy, no more leak.

This Weekend

This weekend I fixed the timing problem and it’s 100% better than it was. In search of lower temperatures at high speed I also changed to 5W20 oil; unlike watercooled engines that regulate their temperature directly with a thermostat, the VW aircooled engines primarily regulate their temperature indirectly via oil pressure. When the oil is cold it’s slightly thicker, causing the oil to compress a spring loaded valve and bypass the oil cooler; once it heats up it becomes thinner, allowing it to flow through the oil cooler in the fan shroud. In this way, the oil temperature is kept under control. However, if the oil pressure is too high even when hot, the oil will still bypass the cooler. In my case the oil pressure is high due to tight bearing clearances from the new bearings, and high RPM. It may get better as the engine breaks in, but for now I’ll just keep it at 55MPH or less except short bursts; the real solution here is getting the RPMs down with different transmission ratios. I also made good progress toward wetsanding and polishing, and got vinyl on order for all interior panels and seats.

“Timing is Everything”

Since the rebuild I’ve had trouble getting the bus to do 65 for more than about 5 miles without getting into the danger zone of overheating. I’ve looked at various things in the process of debugging this but tonight I think I finally found the problem; and it’s related to the way that the ignition timing works…

(Begin technical rant, or just skip to the picture at the end) To adequately explain the problem I first have to explain that in an internal combustion engine the spark is timed so that the explosion in the cylinder is peaking just as the piston is beginning to move down; the explosion pushes the piston down, which ultimately moves the bus. However, the explosion is a chemical reaction, and it takes roughly the same amount of time to occur regardless of how fast the piston is moving; so when the piston starts to move faster (higher RPM) you have to start the explosion sooner to keep the explosion peak at the same place in the cycle. This moving of the spark event is called ‘advance’ and it’s accomplished with a very clever spring and counterweight mechanism inside the distributor, as the engine goes faster the counterweights fling outwards, moving the spark trigger (points) and advancing the timing. Additionally, because higher quantities of fuel take longer to burn, the timing also has to be advanced in proportion to load. This is accomplished by a vacuum canister on the distributor that’s connected to the carburetor, the more air/fuel that rush through the carburetor, the more vacuum is drawn on this canister, moving a push-rod that further advances the timing. I found that the canister on the bus’s distributor had ruptured, causing not only the advance to be too low, but also a vacuum leak (which is also bad for other reasons I won’t get into).

So what it boils down it is that at high RPM under load there is not enough advance due to the ruptured canister, the explosions are happening too late, which means that they’re not as effective, which means that all the explosions have to therefor be more powerful to achieve the same level of power, which means more fuel, which means more heat; and thus the overheating problem. I have a replacement vacuum canister on order which should not only solve the overheating problem but increase MPGs substantially. If you made it through all of that, here’s a picture of the bus from tonight while I was figuring all this out…

Engine Back In!!

After a very long night last night and all of today, the bus is running again. There is a very specific order of assembly, and if this order is violated the engine has to come back out to start over. Although this seems obvious, several of the key early assembly parts are not so obvious. Because of this the engine was in and out a few times.

More Delays

Today I was assembling the cylinders and pistons onto the engine when a piston ring broke. Normally I would be able to go to the local auto parts place and get a replacement ring set, but since the bus had 88mm over-sized cylinders the rings cannot be sourced locally. The 88mm cylinder set is known to cause alot of problems since the cylinder wall is so thin; so I’m taking this opportunity to replace the cylinders/pistons/rings with the standard 85.5mm size. This makes the engine a ‘1600’ (1584cc) again, with the 88mm cylinders it was a ‘1700’ (1679). No changes had been made to the stock cylinder heads, so the ‘1700’ configuration would have needed racing fuel to run with any longevity. The ‘1600’ will be able to run on regular, or at-worst mid-grade.