Carpentry & Aviation

Today (I have a few days off of work), after a few months of studying in my spare time, I finally took the controls of a Cessna 172 for about an hour. With direction from the instructor I taxied, took-off, climbed to 2000ft, and then maneuvered around and even did part of the landing approach; though the instructor did the landing itself. I’ve got a long way to go but over then next year or so I’ll be flying somewhat frequently to make progress towards a private pilot certificate. Anytime a new skill can be learned (i.e. welding/painting/etc from the bus project) I find that it can be beneficial in unexpected ways, even for seemingly unrelated tasks/problems. So this is about having another tool in the mental toolbox, and I’ve always been interested in aviation anyways…

After arriving back from the flight I starting working on installing crown molding in the downstairs bathroom. For some reason this was the only room in the house that didn’t have it and I always thought it looked odd. In the past, I’ve just propped the molding up at the correct angle and hand sawed at 45degrees in a miter box. Due to the number of joints though I decided to get fancy and make the cuts on the tablesaw. This presents a problem since, when the molding is flat on the table, the angles are in two different directions: a compound angle in which the blade must be tilted and the material angled against the push fence. Luckily I’m not the first person to ever do this so I found tables online of compound angles for a given wall angle (90deg nearly always) and a given trim angle (the angle the trim sits against the wall). There was some scrap made while learning what orientation to use for a given angle; 4 of the 8 combinations don’t make anything useful (i.e. inside right/outside left/etc.) More than a few times during this process I thought back to how much easier flying the plane was (or at least seemed) earlier in the day.

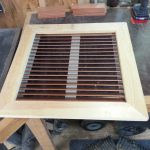

Building a better air return

Today, as part of a repainting project, I constructed a new air return out extra slats from wooden blinds and some scrap wood. Nothing was wrong with the existing metal return other than being ugly, so it will get added to the scrap metal pile and possible used on some metalwork project. All the materials were scraps from other projects, so total cost was just some paint/glue/staples and a few cents of electricity. As a bonus, the new return seems to be quieter and less restrictive than the metal version.