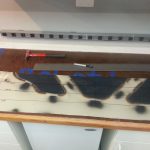

The metal has arrived and over the last few nights I’ve begun fabrication of the machine. For the electronics enclosure I’m re-purposing the original crumpled hood that came with the golf restoration project. After removing the inner support, the outer hood skin was a reasonably flat piece of sheet metal. (That does also make this machine part VW, but it wasn’t intentional) I don’t have a big press brake for accurate bends, so the box that resulted is a little wonky, but its nothing that can’t be salvaged with some body filler and sanding.

I’m moving fairly slowly with the machine base, making sure everything is as square, flat, and true to the design as my ability to measure, and so far it’s looking really good. I also have the gantry mostly fabricated, which consists of two pieces of angle iron welded edge-to-edge, forming a channel.

Remaining:

– Fabricate gantry columns

– Fabricate motor plates

– Fabricate Z axis mounting plate

– Fabricate electrical enclosure lid & connect to base w/ piano hinge

– Machine base flatness check and hand scraping of guide mounting ways

– Drill & tap holes (dozens of them) in the machine base and racks for mounting the racks and guides

– Assemble/Wire/Test

– Disassemble, Paint, & Reassemble