The front bumper over-riders and “towel bar” were assembled onto the front bumper to check the fit of the towel bar. The towel bar came from a different bus and had a fair amount of denting and deformation. Initially the holes did not line up by several inches; a 1/16″ relief cut in exactly the right spot was all that was needed to allow the bar to bend and the holes to all align. Much of the bodywork for the towel bar will be done with it assembled to the bumper to avoid causing any warping that would prevent reassembly. Also, small parts were organized into a rough assembly line, progressing from right to left. Some sub-assemblies are very close to the point where they could be re-assembled but are waiting on a part or two to be finished.

Front Bumper Mock-Up

First Paint on Body!

I haven’t updated in a while; there has been some undocumented progress prior to today however work on the bus was mostly stopped while outdoor spring projects were completed at the house/yard.

Various small parts have been painted prior to this, but this is the first paint on the body shell in 45yrs, so it’s a real milestone. I choose the front dash and nose area because #1 it’s one of the more intricate areas and if I’m having to wetsand/polish anyhow then I may as well start there; potentially if I get good enough with the paint gun later there will be minimal wetsanding/polishing needed on the large flat areas. And #2, the front area has the most accessory pieces over the paint then anywhere else (emblems, gauges, etc.) and if there’s any problem with paint thickness or part fitment I’d rather see it now when it’s easier to fix.

Overall the clarity is good after some extensive wetsanding and polishing, since it’s warmer now I’ll have to dial back on the amount of reducer next time so there are fewer runs to sand out. I let the white blow freely over the body line, this way there is a soft edge for when the blue is sprayed below. Otherwise I’d either have to match two edges perfectly, or there would be a ridge visible under the blue paint.

I couldn’t resist installing the emblem, clock, window weatherstripping, wipers, and even the “one-eyed duck” that holds the wipers away from the safari windows. These will all come off again to be protected from overspray, but it was good to see a few areas look ‘finished’ for the first time.

Engine Tins Media Blasted

Work began on the various sheetmetal parts (known in VW vernacular as “tins”) that direct air to and through the cylinder cooling fins. Being aircooled instead of watercooled, this is one area where the bus has much more in common with a modern light aircraft than any modern road vehicle. These parts are all thin steel and have been exposed to years of extreme vibration and temperature fluctuations; because of this there were many stress cracked spots that required welding.

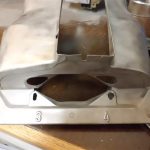

Bumpers Epoxy Primed

The bumpers received another coat of epoxy primer to seal the filled areas. Also, (not shown) the front door window frames were sanded and re-primed. All of these items (bumpers, window frames) are the foundation pieces for many of the small parts painted earlier. Once these parts are completed then the window and bumper sub-assemblies can be built using the refinished parts and new rubber seals.

Small Parts Painted & Bumper Bodywork

Kumulus Weiß und See Blau!

The color coats arrived today; the bus will be Cumulus White on the inside and top, and “Sea Blue” (Lake Blue) on the bottom to match the original color scheme. I was able to get one white part far enough along in the prep process to paint as a color test, it’s an extremely close match to an area of protected original cumulus white I found and polished. Unfortunately the sea blue doesn’t match a protected original sea blue area that I found and polished. There were multiple sea blues in ’67, both sharing the same VW paint code, so that’s likely the source of confusion; one was darker and less green (the original bus color) and the other was lighter with a green/teal tint (what was sent). The paint supplier has been great so far so hopefully this won’t be a problem to fix.

Small Part Progress

Another round of primer was completed on the current batch of small parts being restored. The bumper over-riders are becoming very smooth and the rust pits are no longer visible. In the process of painting the small parts on the opposite side of the garage I found that the over spray that does occur is just dust by the time it reaches the cabinets. Because of this I took down part of the bus bubble to re-gain working room and improve lighting.