Custom Desk – Monitor Lift Mechanism

I got the idea for the monitor lift from an example online using all-thread as lead screws to drive a platform. Essentially I’m just replicating this idea but with a few tweaks that take advantage of having the lathe to make it better/stronger, easier to build, and to take advantage of spare parts I already had.

First I cut the all-thread rod to length and then I turned down one end of each to fit the inside diameter of some spare bearings. I left an extra bit on the end and turned it down to fit the inside diameter of a timing belt drive sprocket – this was later replaced with a chain sprocket due to slipping. I repeated the same on the top side of each rod (without the extra bit for the drive sprocket) and then I cut some metal brackets to hold the outer bearings. I then cut a small platform and attached two nuts to it that would connect it to the threaded rods.

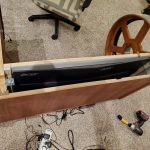

These parts were all assembled into the desk; a few small shims were needed to get the rods exactly parallel. I then connected the threaded rods together with a small #25 chain drive. To power the lift I tried a few different test motors and eventually settled on the guts from a small/cheap electric screwdriver – this provided enough torque while not requiring a huge power supply. It could be a bit faster and I need to add some sound damping, but it’s working very well for an initial attempt.

I also made some mounting plates to adapt the monitors to a fixed mounting since the regular bases were too wide. The monitors were then mounted to a 2×4 that acts as a spacer and also adds strength to the platform. Once the tabletop is in place the 2×4 and the rest of the mechanism will not be visible since the monitors will rise so that their bases are just flush with the top – I’ll likely add a trim piece to block this off. The monitors also drop low enough that the table top will clear with no problems.

The last step was adding limit switches and rewiring – moving the toggle switch up runs the lift up until the positive switch is tripped, and moving the switch down runs the lift down until the lower limit switch is tripped.

Next up will be making the tabletop…

Balalaika Repair

It had been in storage and a few parts were missing that needed to be replaced:

– End Pins – 1 of the 3 end pins remained and I used it as a reference for turning 2 more matching pins on the lathe from a plastic rod.

– Bridge – The bridge was missing but I found dimensions that seemed to match the shadow that had been left by the original bridge; I used these dimensions and some reference photos online to make a replacement out of a scrap of maple. This was very quick work with the belt sander.

– Strings – This was the easiest part, available online.

With the parts replaced we were able to tune it and it seems to play OK…

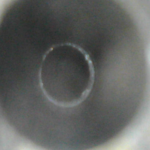

With an endoscope camera I was able to find two labels inside:

Left Translation: Balalaika. Article #205. Airbrush method finish. Nationwide Standard of Russian Soviet Federative Socialist Republic 83-72. Price 6 rubles 70 kopeks. Leningrad, 15 Chapaev St.

Right Translation: Ministry of Local Industry of Russian Soviet Federative Socialist Republic

Main Directorate of Production of Musical Instruments

Lunacharsky Factory of Folk (plucked string) musical instruments

Leningrad

The left label is also stamped with a 1973 date

Window Crank Adapter

It’s not particularly hard to use a window crank, but multiplied by several windows it does take a little bit more time than it could. With this in mind I created an adapter for a cordless drill to more quickly open/close windows, particularly as it’s starting to cool down some and we’re using the windows more.

Construction was relatively straight forward, it’s just a bit of aluminum turned to size and with a hole drilled with the same size as the OD of the splines on the window crank mechanism. The only tricky part was creating the splines since this is the first time I’ve attempted it. The lathe has a built-in index plate that allowed the adapter to be positioned in the 12 evenly divided positions required; once it was in each position I used a small lathe tool to broach a slot, moving the carriage back and forth with the lathe off while slowly raising the tool. I then turned a bit of steel rod to size and pressed it into the back of the adapter.

Overall it turned out OK – the splines aren’t the greatest due to the tool not being very rigid, but it’s plenty good enough for it to engage with the window and hold solidly.

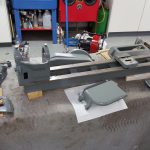

Jet Engine Oil System

This weekend I resumed work on the jet engine project. When I last left off I had just completed the frame and mounted the turbocharger/combustor. I had also fabricated an oil tank out of an old propane tank and mounted it under the turbo, but had hit a bit of a wall with what to do for an oil pump. There are electric oil pumps available, but basically all of them would be overkill for this application. Also, since this is a hobby I’d much rather put in the time to make something custom vs paying for parts. Turbocharger jet engines have been done by many others, my approach with this is to see how compact and well packaged I can make one – that doesn’t happen by bolting together a bunch of off-the-shelf parts.

I had considered using the bus’s old oil pump, but this created more problems than it solved (connection of inlet/output pipes would be a challenge as would driving it and selecting a motor). Today after a taking a fresh look at it I realized that an old 12V tire inflator pump that I had could be adapted to work. The plastic casing had broken, but the ‘guts’ were all metal and should hold up to oil pump duty. The only problem was that the cylinder head of the pump had no way of connecting an inlet pipe – being designed for air, it just drew in air from a small hole. To fix this, I made a new cylinder head on the lathe with one large hole in the center. A tee fitting screws into the head and I’ll put a check valve on each side. This larger single-hole head should also help compensate for the increased load of pumping oil, much thicker than air. Once I start running oil through it I may have to make some tweaks to avoid overload (lower voltage, thin oil, etc) but this at least gives a path forward for experimentation.

I also shortened the oil tank to make more room underneath for other support systems and made a threaded port on the lathe to weld into the tank to connect the oil pump. The welds aren’t the greatest looking, but are leak-free and that’s what matters – they should clean up OK after some grinding. For now the whole project is in fabrication mode, but once everything is in place and working I’ll go back and do body/paint work on all the parts to make it look nice too.