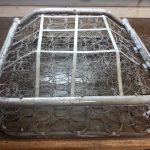

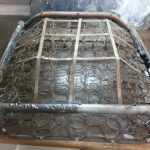

Jacuzzi Hardware Powdercoat

The jacuzzi tub the house came with is big, grey, and (according to a scan of the manual I found) able to pre-fill via a phone call to its land-line modem* – if only land lines still existed. Mechanically though it’s fully sound and there’s no reason to replace it. Doing so would be a major expense even before factoring in the chaos it would create – one wall of the bathroom would need to come out, at a minimum. Much better for now to just freshen up the appearance.

A big part of the objectionable appearance was that the brass hardware (even if polished rather than corroded) doesn’t fit with either of the last two remodels the bathroom has undergone; one from previous owner, one from us. The hardware isn’t available anymore in any color, and paint would quickly scratch off, so this was a great excuse to try powder coating. I picked up a $5 toaster oven, power coat gun, and grey powder coat. Results look great and it seems like it will be plenty durable.

*Replacing/Interfacing to this with an ESP/Arduino/Raspi may be a rainy day project.

Wet-Sanding & Polishing

Today I worked on wet-sanding and polishing; starting with the blue areas. The paint straight from the gun leaves a finish that is shiny, but has the texture of an orange peel. The goal of wet sanding is to level off all the peaks of this orange peel texture so that the paint is flat. First 500grit is used, then 800grit, then 1500grit; the panels are kept wet and rinsed frequently to avoid dust build-up that could scratch the paint. It’s critical that the surface is not sanded below the lowest low spot of the orange peel texture, otherwise primer could be exposed and repainting would be required. Luckily the low spots, being untouched by the sanding block, are visible fairly readily as slightly darker spots. After the sanding is completed the paint is flat, but dull looking from the very fine sand scratches. Polishing with rubbing compound and a rotary buffer brings the shine back. The passenger side of the bus is mostly complete; I’ll likely get the driver side complete by the bus’s first long trip, but I’m unsure about the front/back/white areas.

Engine Compartment Painted

Hatch Painted

See Blau!

All of the hours of sanding on the lower body finally paid off today. Thunderstorms in the area all day prevented me from painting outside; so I moved everything in the garage to the back wall, covered with drop cloths, and painted inside. The only casualty was the garage floor which is being resurfaced in the near future anyways. This worked out better anyhow since the color coat stayed sticky for a long time (compared to primer), if it were painted outside any passing bugs/dust would have stuck. Overall it came out well, you can easily see reflections in the pictures, but it will require wet-sanding & polishing to get rid of the orange peel texture.

After the paint was complete there was no longer anything stopping me from mounting the bumpers and lights, so I got them on right away. It’s nice that these parts are finally going on the bus since they had been taking up a lot of storage/counter space.

Sealer

The last round of sanding only broke through the primer lightly in a few spots, so tonight I added one more coat of primer that will be wetsanded with 400grit; blue paint should go on this weekend!

More High Build Primer

No photos since the bus doesn’t look any different. After several rounds of priming/sanding it is becoming much flatter though and should be ready for blue paint soon.