Crossed Oar Wall Mount

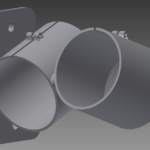

Quick project to mount some oars on a wall for decoration. It looks like the ‘normal’ way of doing this involves leather straps, brackets, spacers, etc. It gets messy relatively quickly and seemed like a lot to align/mount on the wall.I also wanted to leave the oars unmodified, so to avoid all these problems I made a custom steel mount. I first made a mock-up in CAD.

Next I found some steel tubing on the scrap pile that was the right size, cut it to length, and then cut a slot and welded on some tabs for a pinch bolt. The plan was to slide the tube over the handle side of the oar to the middle then tighten the bolt to clamp the oar in place. This didn’t work, because even though it’s not readily visible, the oars have a ~1/4″ taper from the handle end to the center. I had measured the center when sizing the tube, so it wouldn’t fit over the handle. I didn’t want the tube any bigger because it would look odd/oversized in place, so I began making a hinge that would allow the tube to flip open for installation. This effort failed, the tiny bit wandered in the long rod; hinge alignment wasn’t going to work. I then realized that the pinch bolt alone was strong enough to hold the tube halves together and abandoned the hinge idea – if it did need the strength, a bolt on either side would be much simpler.

I then made a mounting plate and drilled a hole in its center and the center of 3 of the 4 tube halves. This hole allowed everything to be bolted together temporarily and aligned prior to welding. It was then welded together, cleaned, and tested. The base was lag bolted into a stud.

All that’s left is to take it down and finish the mount – I will likely use a metal black solution and oil for a natural metal look. The inside of the tube shells will also get a layer of felt to hold the oars securely (The tube size left just enough gap to account for this)

Toro Dingo Platform

Last spring I won an auction for a Toro Dingo TX427 mini skid steer. Uncharacteristic of my usual equipment purchases, it didn’t need anything other than cleaning and an oil change. It came with the standard bucket, and I also later got a pallet fork attachment and a tooth bar for the bucket. Over the last year it’s been extremely useful with various landscaping tasks, as well as moving around pallets of materials for various projects. Mostly though it’s the perfect tool for dealing with downed trees and getting logs to the sawmill or burn pile.

One limitation that became apparent is the machine’s limited counterweight – the back begins to lift well before the hydraulic pressure relief trips. An optional feature from Toro addressed this problem by adding an operator platform, but mine lacked this option. I’d kept an eye out for used Toro platforms, but they weren’t often available and were overpriced – especially after considering shipping. A simplified aftermarket version was available closer to when the machines were new, but these had stopped production.

With that considered I decided to build my own platform based on pictures of the aftermarket version. It consists mainly of an expanded metal stair tread cut in half and welded back together into a square. Two square tubes reinforce the stair tread, and then it all hinges on a length of black iron pipe that runs through brackets sandwiched between the frame and the existing counterweights. Stops were then welded on each side of the platform to hold it level when deployed. When folded up against the back of the machine, a bolt (with 3d printed knob handle) holds it all in place. It’s flat enough when folder to not be in the way for operating while standing on the ground.

Crawlspace Door

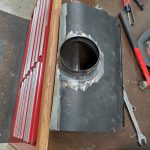

One side of the house had a site-built wooden door. This always bugged me since it’s the only place on the house where wood extended below the wall’s sill plate – everywhere else it was masonry or metal only. This door was vulnerable to rot/termites and also didn’t seal well (mouse risk), so I have been keeping an eye out for a better replacement – with the concrete/drainage being finished in the area this door is the last part of the overall project to remodel the area.

I found a used electrical control panel online that was the correct height, but slightly too wide. Since this was the closest match I had seen and since it was local I picked it up. I first cut the back out of it to the correct depth, then cut a section out of the panel and one of the doors before welding it back together. The door got some minor filler before everything was sanded and painted. The door was then caulked in place and new weatherstripping installed.

Kubota F2000 Wheel Rebuild

Recently one of the wheels on the mower broke. This hub of this particular wheel has always been a weak point and I’ve welded it back at least once. This time it was too far gone though and I intended to replace it… that is until I realized this wheel is a very odd size and offset that’s specific to this series of mowers. It wasn’t clear that replacements were obtainable. With that being the case I decided to machine a new flange that could be welded in place to reinforce the inner wheel. The flange consisted of a 1/4″ steel plate turned down to the right diameter, then center bored and hole pattern drilled on the rotary table. The flange was then welded in the wheel and the back side faced on the lathe to ensure the face of the wheel would be perpendicular to the axle hub.

Audi S4 3.0T Secondary Air Cleaning

Part 1: Background

A while ago my check engine light began coming on sporadically, after scanning I found this was related to P0491 & P0492 errors. These errors indicate that insufficient airflow is available to the secondary air system that’s responsible for getting the exhaust catalysts up to temperature quickly at start-up. These errors would self-clear, but over time the light stayed on longer until eventually it stayed on.

I first checked all the ‘easy’ stuff related to this fault: the secondary air pump and solenoid both worked OK via VCDS and no leaks were found on any of the tubing. I also tested the “combi” control valves which successfully blocked air flow when blowing through the secondary air pipe and allowed air when manually actuated with a vacuum pump. At this point I ran a good amount of seafoam and intake cleaner through the secondary air pipe that goes under the supercharger, using a HVLP paint blower to push it through the system while the combi valves were held open with vacuum – lots of smoke, no change.

This unfortunately left blockages in the cylinder head’s internal secondary air ‘manifold’ as a most likely cause for the problem, there’s a TSB with lots of good info here: https://static.nhtsa.gov/odi/tsbs/2018/MC-10153120-9999.pdf (Required Reading for this topic!)

Options at this point, in order of consideration, were:

#1 – Take it to the dealer for the 120k mi extended secondary air warranty, I had ~110k mi at that point. I strongly considered this, but in the end it didn’t seem worth the hassle. With it being high mileage by their standards I fully expected to get push-back or some excuse for it not to be covered, while potentially being on the hook for their ‘diagnostics’ fees. Either way this was likely to be a less enjoyable experience than wrenching in the garage over a long weekend.

#2 – Buy the VAS6825 tool and do it myself. The TSB has plenty of info to do the job successfully, OK let’s just order the tool and …….. it costs how much?!?!

#3 – Make the tool myself and do it myself. The tool is simple enough, and I was reasonably confident a usable tool could be made at home. I went with the last option, let’s make the tool….

Part 2: Tool Creation

From photos online, the official tool (fig. 1) appeared to just be two smallish diameter flexible pressure washer tubes: one that’s basically a tiny sewer jetter, spraying forward, and the other that sprays out sideways. The main passage can be cleaned manually (coat hanger, vacuum), so only the sideways spraying tool is needed. The sideways spraying tool also comes with two plates, a bushing, and an attached scale to correctly position jet in front of the perpendicular passages while still allowing some movement for wiggling the jet around for better cleaning. For my purposes the whole bushing, plate, and scale arrangement would also be omitted – I’d be using a camera to locate the distance to the passages and then positioning the tool manually. There’d be no damage risk from a misaligned jet, as water doesn’t cut aluminum at 4000psi, so the water would just come squirting back out around the tool. I assume the official tool only has the extra complexity to justify its exorbitant price and to make it more suitable for use in a professional environment.

Figure 1: Official VAS6825 tool

With that settled, I only needed a long tube with a right angle nozzle. The small diameter pressure washer hose they use for this isn’t commonly available and even if it were its not clear that any fittings would fit inside the passage. (They use a crimp connection to get around this, but that’d require expensive crimp tooling in the strange tubing size – big money for something that I’d likely never use again). The good news is that the main secondary air passage is perfectly straight, so there’s no reason for flexibility at all. With this in mind the plan quickly coalesced around using some steel tubing. The tubing I selected was a 3ft length of 3/8″OD with 0.083″ wall thickness (McMaster 89955K459). This thickness is massively overkill vs the 4000PSI of my pressure washer, but a big ID isn’t needed for flow and I was more concerned with having enough metal thickness to get good welds.

From there I took a spare chunk of 1/2″ round bar, bored a 3/8″ hole to accept the tubing, and tapped the other side to 1/4″NPT for the pressure washer coupler. (fig. 2) I did this on a lathe, but it could be done with a drill press or drill/vice if centered carefully. This was then welded* to the tube on one side along with a simple plug on the other.(fig. 3) At that point I had a fully sealed tube to which I drilled an ~0.043″ hole on the side of the end, giving me the right angle jet. (fig. 4) The hole size depends on the specs of the pressure washer, check tables online, 0.043″ was right for 4000PSI / 3.5GPM. The official tool appears to have 3 holes – I suppose you could calculate the right hole sizes for this and do it that way, but the single hole is already tiny and any performance loss from this is easily overcome by wiggling the single jet around more/longer. Lastly, add a line along the tool so it’s clear which way the nozzle is pointing. Total cost less than $30.

Figure 2: Making the end adapter

Figure 3: End adapter welded to tube, coupler fitting attached

Figure 4:Nozzle Orifice Drilled

*Warning: This is effectively a DIY hydraulic line under a few thousand pounds of pressure. It can

fail forcefully with risk of injury.

Part 3: Cleaning

As always, remove the entire front of the car using whatever method/sequence you prefer. You’ll need unobstructed access to the front of the engine. I was able to suspend the bumper/radiator support from the ceiling and hinge it open like a gate to avoid disconnecting the AC lines. Note though that this puts strain on the upper radiator hose and that will crack the coolant crossover pipe, so disconnect it first. I only left the hose connected because I couldn’t get it off the pipe without destroying it, so it was probably doomed either way.

Get access to the secondary air ‘manifold’ freeze plugs (fig. 6); there are a number of things in the way (belts, coolant flange, hoses, etc) but if you’ve gotten this far you’ll figure it out. Pop one side of the freeze plug with a drift punch and it’ll rotate so you can yank it out with needle nose pliers. Remove coils and plugs at this point also.

Figure 6: Secondary Air Passages from the front of engine

Next use the right angle camera mirror to find the air passages with the angle of the exhaust manifold flange for reference. The passages are drilled straight from the flange (where they dead-end) up to the back of the exhaust valves. Point the mirror up in that direction, it’s the part of the passage that goes up into the valve that we want to clear, the other part that dead ends onto the back of the exhaust flange is only there because it’s much easier for them to manufacture the head that way. Once the passage is centered in the field of view mark the camera cord where it enters the cylinder head, I used colored electrical tape with different colors for each bank; repeat for all 6 passages. (fig. 7) Reference measurements in table 1.

| Driver (US) | Passenger | |

| Front | 75mm | 45mm |

| Middle | 165mm | 135mm |

| Rear | 255mm | 225mm |

Table 1: Distance from Port Edge to Passage Center

Figure 7: Marking the individual passage locations

Warning: Make sure the camera body is securely attached to the cord! Even though my camera (depstech) appeared to be one piece it decided to separate – the cord pulled out and left the camera guts and front body in the passage. This could be disastrous as you’d then need to drop the transmission to pull off the combi valve to push the camera body out from the other side. I was extremely lucky this happened close enough to the end that I was able to access it with small needle nose pliers and pull it out. It re-assembled no problem, the cord had a connector inside the camera body. After that I epoxied the cord to the camera body and wrapped them together with electrical tape for extra insurance.

Next put the camera and cleaning tool next to each other with the mirror and nozzle orifice aligned and transfer all the markings onto the cleaning tool.(fig. 8) All that’s left at this point is to drop the exhaust before the catalysts, setup a big storage container to catch the water, insert the tool, and start blasting. (fig. 9) You’ll also want a catch container up front under the tool, drape a wet rag (if it’s dry it’ll blow away) over the tool so that the water coming out will hit it and drop into the catch container. Insert the tool to the depth of the first marking and rotate so the line on the tool is facing the right way (the same angle you found the passage with the mirror). Set a timer for 3min and pull the trigger. You’ll get an initial blast of dirty water from the main passage as the jet eats through the blockage, this should pass almost instantly. If it doesn’t, you’re off-target – try rotating and moving the tool in/out until water stops blasting out of the front. It’s very apparent when you’re on-target, no water comes out of the front and there’s a satisfying gurgling noise. For the remainder of the time I just moved the tool in/out and rotated back/forth, changing direction when water began coming from the front. Repeat for all passages.

Figure 8: Transferring passage depths to cleaning tool

Figure 9: Blasting! (not shown aligned)

Once complete, use a vacuum extractor to try to pull water from all the plug holes. It was clear during blasting that one exhaust valve was open on each bank, and these two cylinders did have a little bit of water. Next crank it a few times with the plugs out as a precaution before fully reassembling and clearing all the codes.

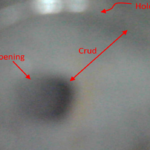

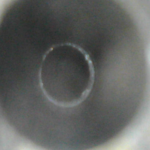

The camera had a hard time focusing on the clogged ports, I had to really work to get usable pictures but you can see a very small dark area in the middle of the before shots – I believe these were the only open area and you can definitely see the edge of the port, so everything in-between was crud. (fig. 10) After cleaning I got great pictures with no effort at all that immediately showed fully clear. (fig. 11) The process was a success and the code has not returned as of many months later.

Planer Dust Collection

Quick fabrication project to add a dust collector connection to the planer. The planer generates by far the most chips/dust of any tool, so this will be a welcome addition.

Chainsaw Sawmill v3.0

With the general success of the prototype chainsaw sawmill, I decided to make a more permanent/cleaner version. The idea is basically the same, but for easier installation/removal I decided to have this version clamp onto the bar rather then tie into the handle geometry. This version also allows for finer adjustment of thickness of cut via a sliding fence. (the previous version was only adjustable by adding/removing shims)

Piano Automation Continued

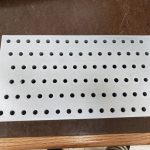

Over the past week I finished the lower valve manifold plate. The lower plate connects the row of holes on the piano tracker bar to the valves on the top plate. Obviously it would have been nice to just put the valves directly over each hole, but since the valves are much wider than the hole pitch I had to instead design the manifold with the valves arranged in multiple rows. Each tracker bar hole is connected to the valve above via passages that are routed into the bottom plate. The path of each passage was chosen carefully to avoid connecting to other valves/passages and to avoid running into the bolt holes that connect the manifold halves – each valve should connect to exactly one tracker bar hole. I let the CNC router do this work; it was relatively slow going with a 1.5mm end mill in aluminum but it turned out OK.

After the passages were milled I created a gasket using wide tape. The tape covers and seals the top of the passages and a hole punched at each valve location allows each valve to connect to its passage. The tape has enough compression that any imperfections in the plates will be sealed once the plates are bolted together. I also added a lip/shelf to the back of the manifold to hold it in vertical alignment against the tracker bar.

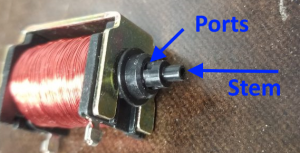

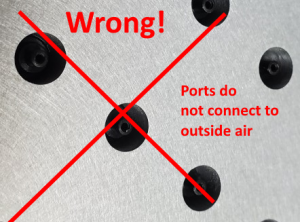

With the manifold ready, I connected it to the piano and tried firing the outputs. Results were not good, there was some vague correlation between outputs being on and notes being played but something was wrong. I had originally assumed the air passed all the way through the valves but closer examination revealed that they actually pass air from their stem to ports near the base of the stem. Since I had the entire stem/base of the valve mounted inside the manifold there was nowhere for air to flow when the valve opened. I re-made the top plate with smaller holes and re-installed the valves with only the stem in the manifold.

Remaking the top plate solved the valve problem but there were many dead notes due to air leaks at the tracker bar. I experimented with several materials to seal the tracker bar to the manifold and ultimately landed on thick rubber outdoor electrical tape as the best performing, though many leaks remained. I found that the tracker bar was not very flat and I was able to carefully bend it back. This helped considerably but leaks still remained. I found that the force needed to push the manifold against the tracker bar for a good seal had the effect of bowing the tracker bar away from the manifold in the middle, so I added a thin aluminum lip to the shelf on the back of the manifold. The lip is just thin enough to fit between the tracker bar and the wood cover behind it and it allows the manifold to hook over the top of the tracker bar and more positively hold the bar along the entire length of the manifold with enough preload on the tape to seal. This essentially solved the leak problem.

Currently there are ~12-15 keys that I’m tracking down problems with, this started from ~20 and was reduced by working through electrical/alignment problems. On the remaining dead keys I’ve ruled out problems on the piano side, problems with the lower plate, and any electrical problems; so next step may be replacing the valves themselves. It’s possible that those keys need more airflow, which would require milling their passages deeper and/or modifying the valves; hopefully it doesn’t come to that. Once they’re all firing though then the mechanical work on this is basically done and I’ll be able to shift focus to the control system side.

Piano Automation Begins

This weekend I designed and began fabrication of the parts needed for adapting the solenoid valves to the piano’s tracker bar. This adapter will consist of two 3/8″ aluminum plates. The top plate will have holes to accept the solenoid valves, and the bottom plate will have holes to interface with the piano’s tracker bar. Grooves will be machined into the bottom plate to create airs channel between the tracker bar holes and the solenoid valves above. The two plate will then be sealed together, covering the grooves; a similar construction technique as some carburetors. As long as the grooves are carefully routed, each valve should connect to exactly 1 tracker bar hole.

I cut the 3/8″x6″ plate on the band saw and then milled to final length. I used an edge finder to locate the plate edges, and then used the mill’s digital readout to position above each row/hole. For each row I took 2 passes, first spot drilling with a center drill and then drilling to size with a twist drill. 88 * 2 plates * 2 passes = 352 cycles of positioning the X axis and drilling a hole. Once all the holes were drilled I sanded sides to remove burrs from the holes and scratches from the rough plate.

Next I installed and wired the solenoid valves in the top plate. The solenoid valves are an exact fit to the hole, but I added a bit of CA glue to ensure they stay in place. Wiring consists of scrap Ethernet cord that’s been stripped back; Every ~7 solenoids each share a common wire to reduce wiring, but it’s still ~100wires.

I’m happy with the results so far; this is by far the most precise thing I’ve made on the mill and everything is lining up perfectly. The next step will be to 3D model the grooves and convert these to paths to run on the CNC router. I’ve done some aluminum milling with it previously so it should work out OK, especially since it’s just cutting the shallow grooves – I wouldn’t have trusted the router to drill the holes as well as the mill did.

Kubota F2000 Snow Plow

We don’t get much snow here, but when we do it takes a lot of shoveling to get out to the road. If conditions are just right we can be stuck for several days waiting for it all to melt. As a result I’ve had a mower/atv sized plow on my watch list since last winter. Recently a new open-box plow popped up that, after factoring in their free shipping, I got for basically scrap value or less. I think the reason for the low price was that it had originally been part of a kit, but all the mounting parts were missing. For my purposes that’s OK though – no one makes a kit specific to the F2000 anyways, so I was always going to need to fabricate the mounting parts myself.

Making the mounting bar just consisted of cutting some 1″x2″ tube to length, squaring off the cuts on the mill, drilling holes for the pins, and then welding everything together. From there the plow’s base just clamped between the mounting bar and another section of tube.I made the clamping bolts fit just inside the plow base’s big hole so the plow can be rotated by loosening the bolts. Since the push bar connects to the standard implement mounting points, the plow can be raised/lowered the same way as the mower deck. I also needed to make some stepped bushings on the lathe to fit the plow base to the plow.

Kubota doesn’t list a tow/plow rating for the F2000, but it’s 4WD with a 3 cylinder diesel and built exactly the same as a ‘normal’ compact tractor, the only difference is that its seating position is spun around 180deg. For occasional plow usage I don’t foresee any issues. I may need to tie into the plow base’s rear holes for stability and to prevent unwanted rotation, but I’ll try it out first to see if this is necessary.

As part of the plow installation project I also went through the mower’s electrics and replaced a lot of corroded connectors with solder/heatshrink splices. It turns out the glow plugs hadn’t been working all along. With the glow plugs now working it starts a lot faster and in winter this will likely be a necessity to start at all.