I rented a huge stump grinder this weekend to take care of the stumps from the various trees that have been taken down. The stump grinder moves incredibly slowly, so I moved it around the yard on the trailer with the mower.

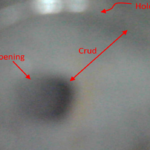

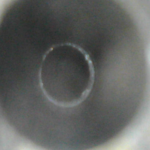

S4 Coolant Leak Tool

I noticed a small coolant leak on my car recently. It wasn’t clear where it was coming from, only that it was somewhere in the front and only occurred after running for some time. To help troubleshoot this I created a 3d printed adapter that interfaced a tire schrader valve to the coolant tank, sealed with an O-ring. An F clamp held this adapter in place and I pressurized the coolant system to a few PSI. This lead to the discovery of a bad O-ring on one of the coolant crossover pipes at the supercharger, which was easily fixed.

Sidewalk Project: Nearly Complete

The next two phases of the garage sidewalk project have been completed. The first of these was relatively easy, just a flat section in an alcove between the house and garage. A channel drain was added at the roof drip line and conduit added for future utilities to access the area (hopefully fiber eventually). The second phase was not as simple since there were heat pump units in the way. To get around this I installed a ledger board to the wall framing then made a frame out of old landscape timbers, with the frame legs outside the concrete area. The units were then carefully lifted onto the frames with ratchet straps, making sure not to stress any of the electrical/refrigerant connections. Concrete was then poured the same as before.

Next phase is one more small section from the heat pumps to the end of the wall, this will catch the rest of the rain run-off and direct all of it into a pipe that will run under the grass.

Commodore 1541 Disk Drive Repair(?)

I spent a long time this weekend troubleshooting a Commodore VIC1541 disk drive only to have it spontaneously start working. I cleaned the belt, de-oxidized the connectors, re-flowed some suspicious looking solder joints, and tried a variety of different disks. Its working reliably now though and I’m able to use it as a bridge between the internet and the C64 via a ZoomFloppy. The ZoomFloppy connects the 1541 to a PC via USB so that disk images can be written and then later loaded on the C64.

Glass Bi-fold Doors

The home office has some bifold doors connecting it to the foyer. Normally I’d like to leave these doors open since it allows light & visibility to the front door, but that would also allow cats to enter the office (usually at the worst times). The solution seemed to be changing to bifold doors with glass panels, however these are very expensive. Since the existing doors were already good quality solid wood though, a good compromise seemed to be modifying them to add glass. I was able to find tempered glass for a reasonable cost online, so I went ahead with this project. Tempered glass is the key since it will break into small (less dangerous) pieces, it’s a code requirement for doors in most locations. The process went as follows:

- Cut a middle section out of the panels on each door. This allowed room for the next step.

- Pull the remnants of the panel edges out of the groove in each door frame.

- Route one side of the door frame flush with the bottom of the groove.

- Install glass panel.

- Make trim piece to hold glass in place, this piece basically replaces the piece of the original groove edge that was routed away.

- Carefully tack trim in place.

- Fill/Sand/prime/paint trim pieces.

Apple IIc Monitor Refresh

Following-up on the Apple IIc computer refresh, I recently cleaned up the IIc’s monitor. Disassembly of CRTs can be dangerous due to high voltages, but at the point of disassembly it had been unplugged for a few weeks and I made sure to discharge the tube and capacitors as soon as I could. From there it was just a matter of cleaning the plastics, using a magic eraser for scuffs, and de-yellowing. The de-yellowing is accomplished by covering the surfaces in peroxide, putting the parts in bags, and then submerging those bags in a bath of hot water kept warm by a sous vide heater.

A few of the potentiometers for size/position/brightness were dirty, causing the picture to cut out unless adjusted perfectly. This was resolved by spraying some contact cleaner under the knobs and exercising them.

Sidewalk Sequel

The next phase of the garage sidewalk project has been completed. Same process here, but a larger section was made possible by the addition of a concrete mixer. At the same time the old railroad timber steps to the back door were replaced with concrete. Next phase will be filling in an alcove between the garage & house (along with adding a channel drain to finally catch water from that area) and then last a section under the heat pump units.

S4 Clutch Replacement

The clutch on my car finally started slipping when under full power. This wasn’t completely unexpected since it originally came from a high-traffic area of NJ. I was able to get it replaced over the past two weekends plus a couple of weeknights. There wasn’t anything particularly difficult about this and it’s well documented online, just lots of small challenges in a row with figuring out how to access various fasteners.

While I was at it I took the opportunity to replace belts, plugs, change the supercharger oil, etc.